Solar Cable, Solar Power Cable, Solar Power Wiring

A solar cable is the interconnection cable used in photovoltaic power generation. Solar cables interconnect solar panels and other electrical components of a photovoltaic system.

Certification Standards

Implementation Standards

- EN 50618

- IEC 62930

Product Introduction

Solar Cable Overview

A solar cable is an electron beam cross-linked cable rated at 120°C that can withstand harsh weather conditions and the mechanical shock of the equipment to which it belongs. Solar technology will be one of the green energy technologies of the future, and solar photovoltaic (PV) is becoming more widely used internationally.

Product Features

- Resistant to ozone, UV, and water vapor

- Lead-free, halogen-free, flame retardant, very low smoke emission

- Oil resistant – chemically resistant

- Conductor temporary overload up to +400 °C

- Ambient temperature -40°C to +110°C (TUV limit +90°C)

- Excellent flexibility under low-temperature conditions

- Resistant to cuts, tears, and crack extensions

- Insulation and outer sheath can be peeled off in one go

- Service life of more than 20 years (up to +90°C)

- Compatibility with standard connectors and connection systems

- Anti-bacterial, anti-microbial

Technical Specifications

- Rated Voltage: 1000V AC, or 1500V DC

- Conductor Material: Tinned Copper

- Number of Conductors: single-core/ dual-core

- Cross Section: 1.5 mm2~95 mm2

- Insulation: Low smoke halogen-free (LSHF), XLPO

- Outer sheath: Low smoke halogen-free(LSHF), XLPO

- The High Voltage Test: AC 6,5kV, or DC 15kV

- Working Temperature: -40℃~90℃

- Max. Conductor Temperature: 120℃

- Standard: EN 50618/IEC 62930

- Certification: International TUV certification

- Sheath Colour: Black (Other colors available on request)

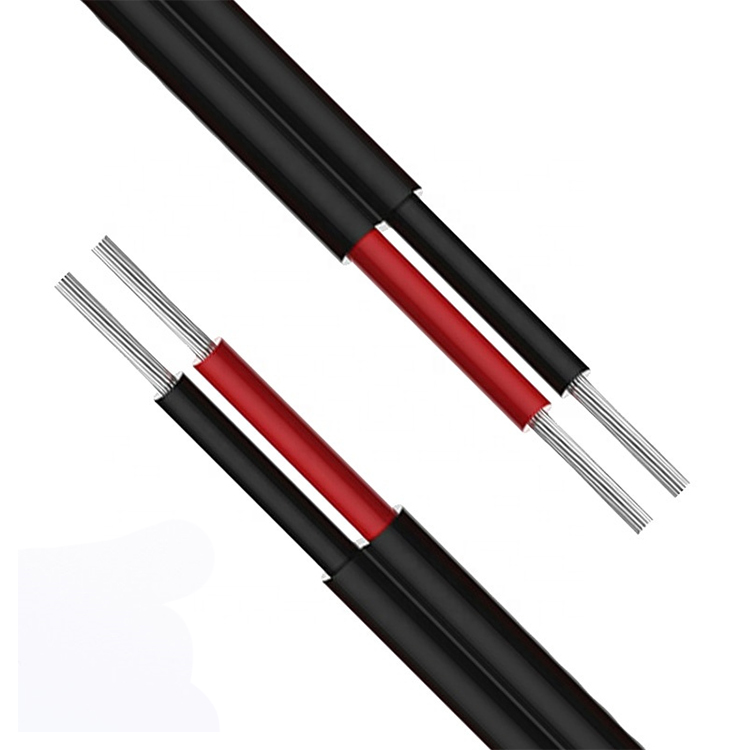

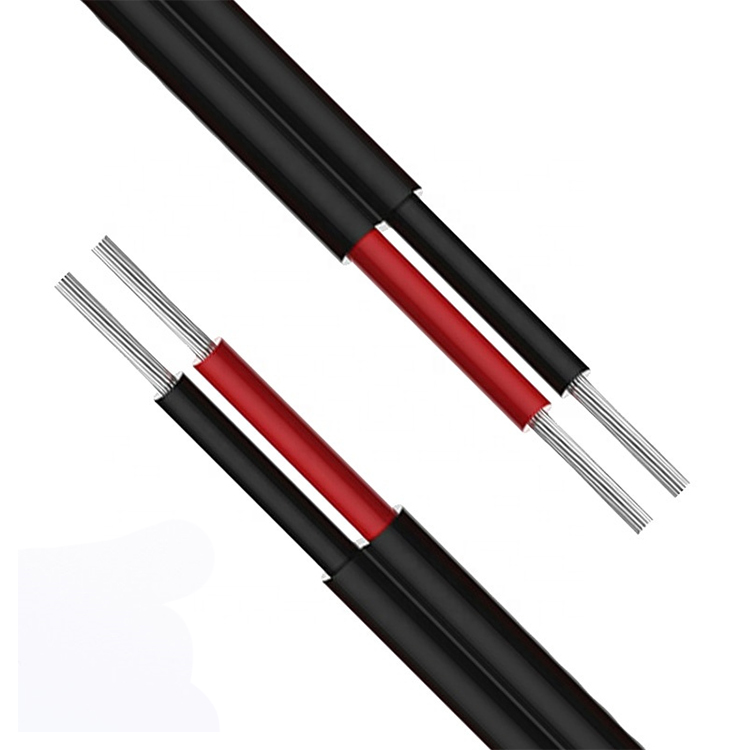

Structure of Solar DC Cable

- Conductor: Tinned copper wire soft conductor twisted together.

- Insulation: Halogen-free low smoke flame retardant irradiated cross-linked polyolefin.

- Sheath: Halogen-free, low smoke, flame retardant irradiated cross-linked polyolefin.

Environmental Adaptability

For photovoltaic applications, materials used outdoors should be based on UV light, ozone, drastic temperature changes, and chemical attack. Solar systems are often used in harsh environmental conditions, such as high temperatures and UV radiation. The advantage of solar cables is that they are rated for 120°C (20,000 hours of use). This rating is equivalent to 18 years of use at a continuous temperature of 90°C. And when the temperature is below 90°C, the service life is even longer.

Selection of Photovoltaic Solar Cables

The cables used in the low-voltage DC transmission part of solar photovoltaic power generation systems have different requirements for the connection of different components due to different usage environments and technical requirements. The overall factors to be considered are the insulation performance of the cable, heat, and flame resistance, aging performance, wire diameter specifications, etc.

Technical Specifications

Solar Cable Specifications

| TYPE | Cross Section | Conductor Structure | Conductor Diameter | Outer Diameter | Conductor Resistance | Rated Voltage | Rated Current |

| mm² | No.OD (mm) | mm | mm | Ω/Km | V AC/DC | A | |

| 1 | 2.5 | 49/0.25 | 2 | 5.2 | 8.21 | 1000/1800 | 30 |

| 1 | 4.0 | 56/0.30 | 2.6 | 6.2 | 5.09 | 1000/1800 | 50 |

| 1 | 6.0 | 84/0.30 | 3.3 | 7.2 | 3.39 | 1000/1800 | 70 |

| 1 | 10 | 74/0.40 | 4.4 | 8.3 | 2.12 | 1000/1800 | 95 |

| 2 | 2.5 | 49/0.25 | 2 | 6.2*9.90 | 8.06 | 1000/1800 | 30 |

| 2 | 4.0 | 56/0.30 | 2.6 | 6.9*11.30 | 4.97 | 1000/1800 | 50 |

| 2 | 6.0 | 84/0.30 | 3.3 | 7.1*14.50 | 3.52 | 1000/1800 | 70 |

Application Fields

Solar farms

Rooftop solar installations

Floating power plants

Photovoltaic power systems

Connection between photovoltaic solar panels

Packaging & Shipping

All cables will be packaged in different materials based on their outer diameter and net weight, and can be customized according to requirements