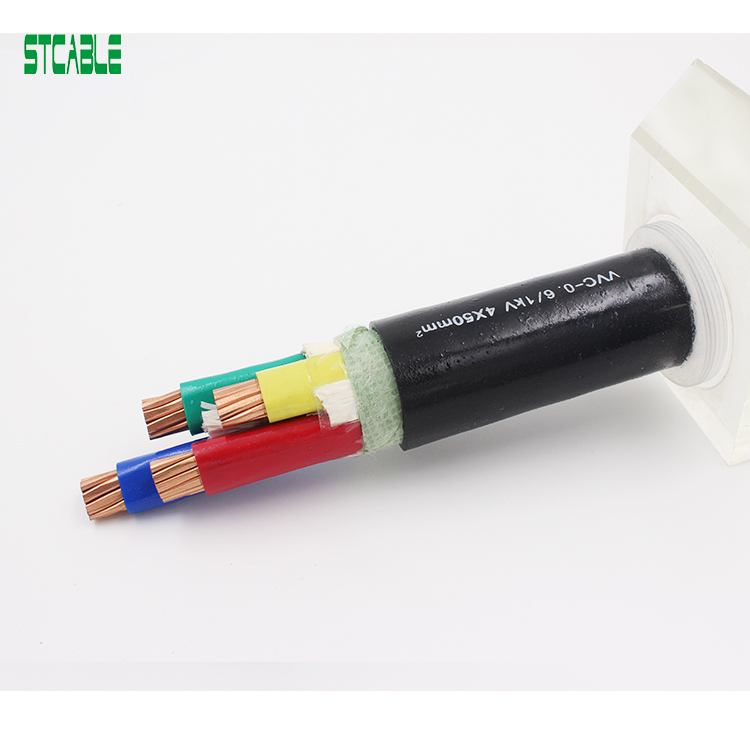

XLPE PVC Insulated Power Cable

XLPE PVC Insulated Power Cable is used indoor or outdoor, in tunnel, cable furrow or pipe, to be laid underground, be applicable to the well, water inside and fall in the bad soil.

Certification Standards

Implementation Standards

- DIN VDE 0276-620

- HD 620 S1

- DIN/BS EN 60228

- BS EN / IEC 60332-1-2

Product Introduction

Product Details

- Construction:

- Cu (AL) /XLPE / Copper Tape Screen / SWA (STA) / PVC Power Cable (3 CORE)

- Cu (AL) / XLPE / Copper Wire+Copper Tape Screen / AWA (ATA) (1 CORE) / PVC Power Cable

- Core Options: Single Core / Three-Cores

- Standards: GB standard, International IEC standard, American ASTM standard, British BS standard, etc.

Features

- Integrated Intelligent High Voltage XLPE Cable:

- Online monitoring of operation parameters

- Real-time monitoring of cable's actual operating temperature

- Online temperature measurement and control

- Online fault location

- Improves operation load of the cable system

- Online monitoring of partial discharge, current carrying capacity, and outer sheath condition

Applications

- Medium voltage cables for distribution networks

- Connection to generation units and plant and process connection

- Laid directly in the ground, outdoors, indoors, and in cable ducts

Cable Standards

- DIN VDE 0276-620

- HD 620 S1

- DIN/BS EN 60228

- BS EN / IEC 60332-1-2

Using Features

- Rated Voltage: Uo/U: 3.6/6kV, 6/10kV (11kV), 12/20kV (24kV), 19/33kV, 26/35kV (35kV)

- No. of Core: Single core or three cores

- Operating Temperature:

- Long-term: 90℃

- Short-circuit (Max. 5 seconds): 250ºC

- D.C. Resistance: Complies with 12/20kV (24kV) stipulations

- Environment Temperature: No lower than 0℃ when laid (preheat if necessary)

- PVC Insulated Cable: Laid without a horizontal drop limit

Testing

- Working Frequency Voltage Test: 3.5Uo/5min without puncture

- Partial Discharge Test: Discharge volume ≤ 10pC under 1.73Uo

Minimum Bending Radius

- Single Core:

- Fixed: 15x overall diameter

- Adjacent to joint or terminations: 12x overall diameter (with controlled bending)

- Three Core:

- Fixed: 12x overall diameter

- Adjacent to joint or terminations: 10x overall diameter (with controlled bending)

Concentric XLPE Insulated Cable

- Conductor: Aluminum / Copper

- Insulation: XLPE

- Core: Single / Two / Three / Four core

- Inner Sheath: PVC

- Concentric Conductor Layer: Copper / Aluminum

- Cable Tape: Non-absorbent Material or OEM

- Outer Sheath: XLPE / PVC / PE

Sheathed Screening PVC Cable

- Conductor: Copper

- Insulation: PVC

- Core: Single / Medium core

- Inner Sheath: PVC

- Screen: Copper (Plastic) or Aluminum (Plastic) Composite Tape, Copper Wire Braided

- Outer Sheath: PVC

PE Insulated Power Cable—Solar Power Cable

- Model: Solar power cable

- Conductor: Flexible stranded tinned copper conductor

- Insulation: PE / XLPE

- Sheath: XLPE / PVC / Customized

Quality Certifications

- ISO 9000

- ISO 9001

- ISO14000

- ISO14001

- ISO18000

- CE

- IEC

- BS

- NFC

- ASTM

- DIN

Packaging

- Wooden reels, corrugated boxes, and coils

- Cable ends sealed with BOPP self-adhesive tape and non-hygroscopic sealing cap

- Waterproof material marks on the outside of the barrel as per customer requirements

Technical Specifications

Packaging Specifications

SiTong Cable cable packaging is provided in the form of wooden reels, corrugated boxes, and coils.

The cable ends are sealed with BOPP self-adhesive tape and a non-hygroscopic sealing cap to protect the cable ends from moisture. We can print the required marks on the outside of the barrel with waterproof material according to customer requirements.

Application Fields

Underground power transmission systems

Power distribution networks in urban areas

Industrial plant power supply systems

Renewable energy grid connections

High-rise building electrical installations

Packaging & Shipping

All cables will be packaged in different materials based on their outer diameter and net weight, and can be customized according to requirements