Cu(AL) / XLPE / SWA(STA) / PVC Power Cable

AL/CU Conductor XLPE Insulated SWA(STA) Armoured PVC Sheathed Power Cable

Certification Standards

Implementation Standards

- IEC60502-2

- IEC 60228

- IEC60332

- BS 6622

- ICEA S-66-524

Product Introduction

Application

Power cables for power networks, underground, and in cable ducting.

Features

-

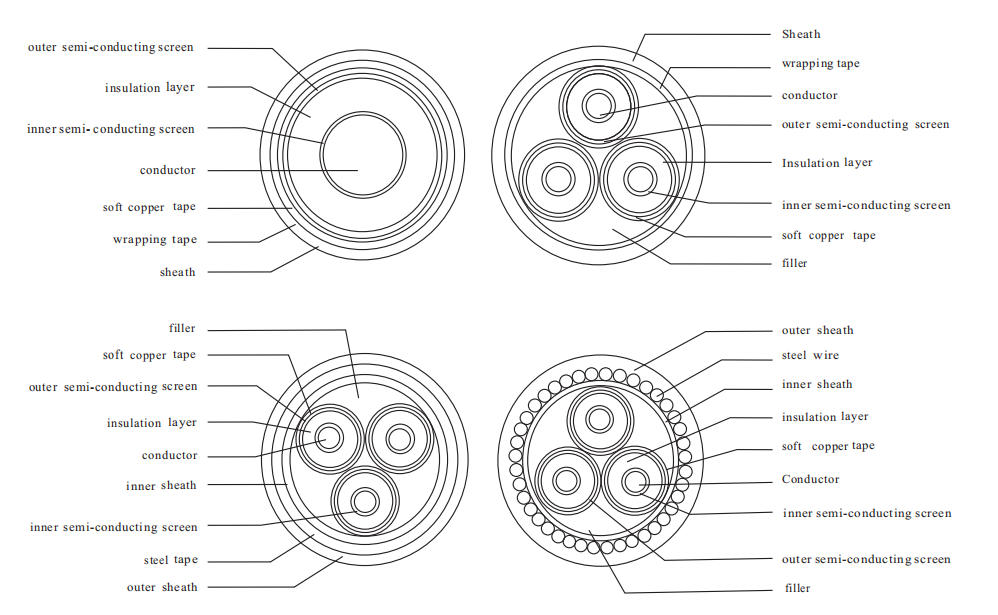

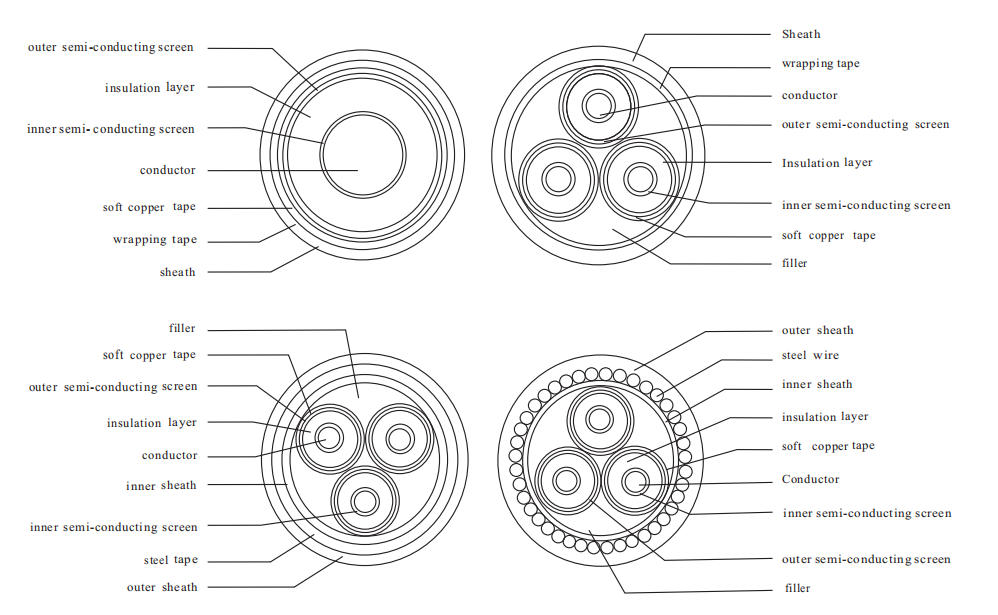

6/10 kV Cu(AL)/XLPE/SWA(STA)/PVC Power Cable (3 CORE) AND 6/10 Cu(AL)/XLPE/AWA(ATA)(1 CORE)/PVC Power Cable

- Cross-linked XLPE insulation electric power cable has excellent electric and mechanical properties.

- Powerful resistance against chemical corrosion, heat aging, and environmental stress. -

Crosslinked 6/10kv XLPE Insulated Cable

- Simple structure, convenient to use, and can be laid with no restriction of different levels.

- Long-term operating temperature is 90°C, and its transmission capacitance is large.

Production Standards

- Flame retardant and non-flame retardant series of XLPE power cables.

- Produced according to specifications equivalent to GB12706, IEC60502, IEC60332, IEC60754.

- Some indexes are superior to the above standards.

Service Conditions And Parameters

- Suitable for distribution lines with A.C. 50HZ and rated voltage up to 35kV.

- Stable capability, advanced technology, broad material resources, low price, good flexibility, and ease to lay and maintenance.

- Long-term permissible operating temperature of the conductor shall not be higher than 70°C.

- Conductor maximum short circuit (less than 5 seconds) temperature shall not be higher than 160°C.

- The cable is not limited by a drop in level when being laid, and the environment temperature shall not be lower than 0°C.

- Perfect chemical stability, resistance against acids, alkalis, grease, and organic solvents, and flame retardance.

- Lightweight, perfect bending properties, installed and maintained easily.

Conveniently

- MV (10kv 11kv 15kv) Power Cable

- Model and Description Uo/U(Um)=3.6/6(7.2), 6/6(7.2), 6/10(12), 8.7/10(12), 8.7/15(17.5)kV

- No. of Core Conductor cross-section area (mm2) XLPE Insulation

- 1 core 3 core

- 10 16 25 35 70 95 120 150 185 sq mm

- Cu core PVC sheathed power cable

- Steel tape armoured, PVC sheathed power cable

- The steel wire armoured, PVC sheathed power cable

- Al Core PVC sheathed power cable

- Steel tape armoured, PVC sheathed power cable

- The steel wire armoured, PVC sheathed power cable

Technical Specifications

Specifications

| Temperature Rating | Fixed: 0°C to +90°C |

| Conductor | Class 2 Stranded Copper or Aluminum Conductors for Single Core and three-Core Cables |

| Conductor Screen | Semi-conductive XLPE (Cross-Linked Polyethylene) |

| Metallic Screen | Individual or collective overall copper tape screen according to BS 6622 |

| Insulation | XLPE (Cross-Linked Polyethylene) |

| Insulation Screen | Semi-conductive XLPE (Cross-Linked Polyethylene) |

| Minimum Bending Radius | Single core - Fixed: 15 x overall diameter 3 core - Fixed: 12 x overall diameter |

| Armour | Single core: AWA (Aluminium Wire Armoured) Multi-core: SWA (Steel Wire Armoured) |

| Sheath | PVC (Polyvinyl Chloride) Type TM1 according to BS 7655 |

| Filler | PET (Polyethylene Terephthalate) fibres |

| Core-covering | Binding tape |

| Min. bending radius | 15 times cable radius (single core), 12 times cable radius (multi cores) |

Application Fields

Power networks

Underground installation

Cable ducting

Distribution lines

Industrial power supply

Packaging & Shipping

All cables will be packaged in different materials based on their outer diameter and net weight, and can be customized according to requirements