12/20KV N2XSY Cable power cable

Power Cable

XLPE

Medium Voltage

Copper Core

PVC Sheath

6/10KV 12/20KV 18/30KV Copper Core XLPE Insulated PVC Sheath N2XSY Cable

Certification Standards

ISO 9001

IEC

CE

Implementation Standards

- IEC 60502

- HD 383

- HD 620.1

Product Introduction

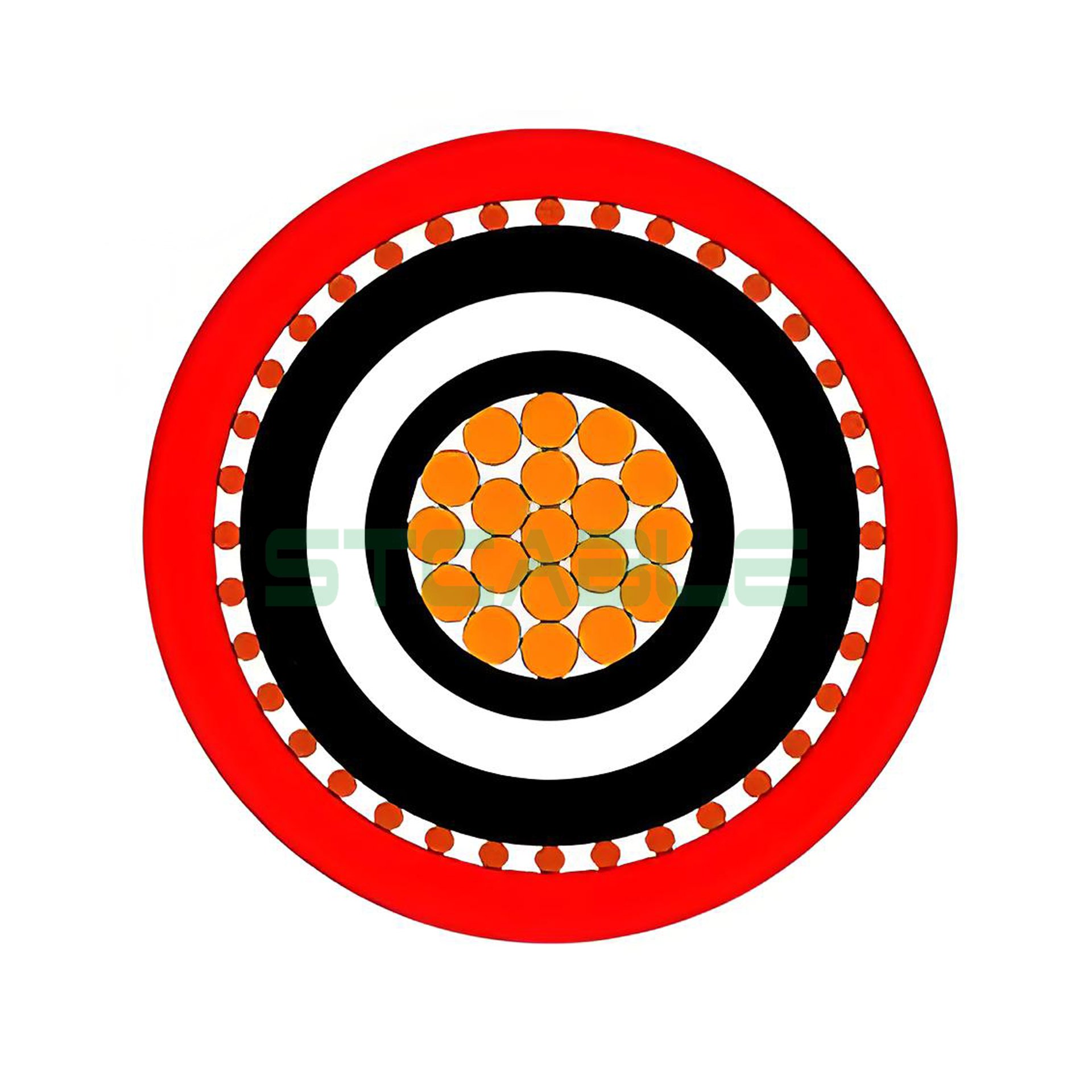

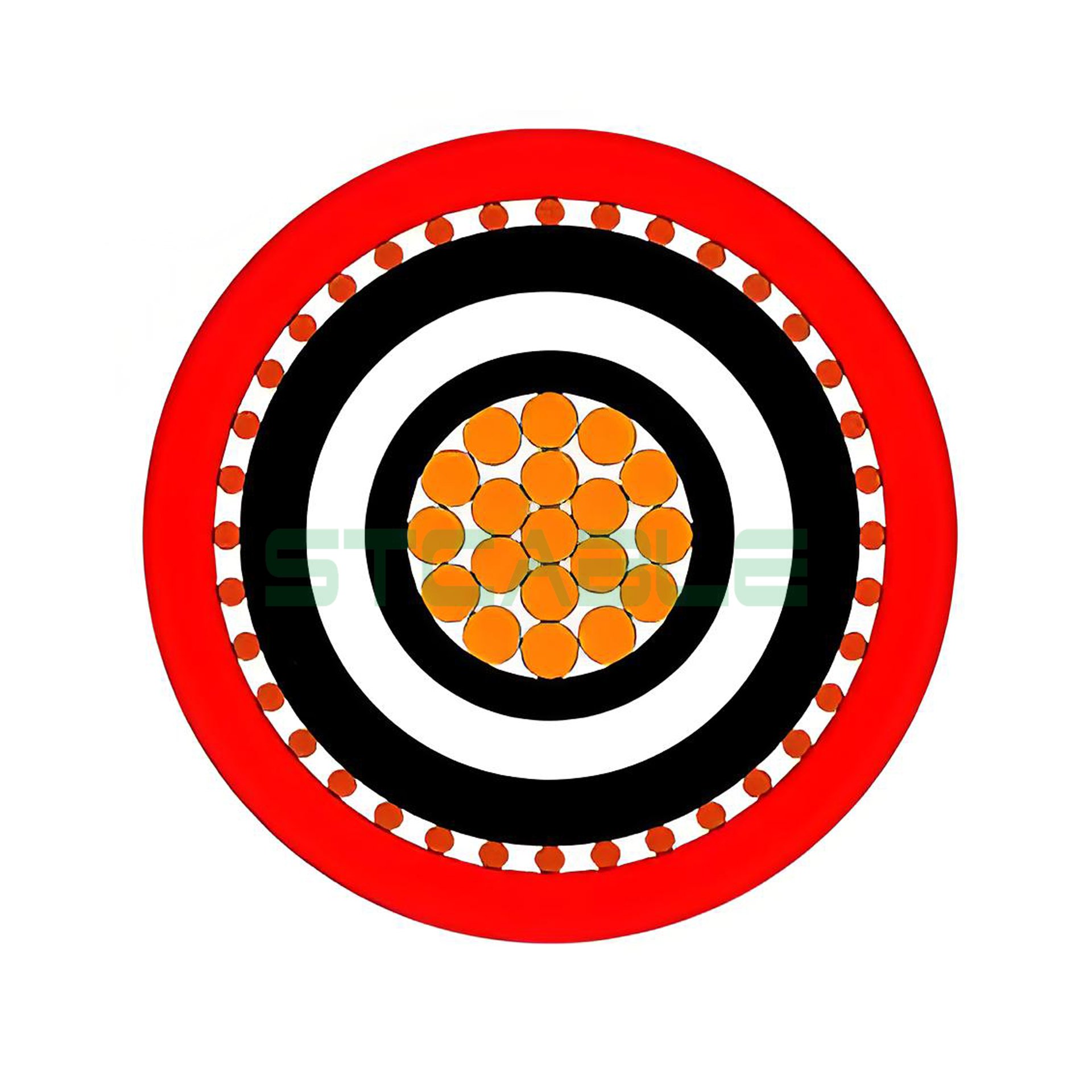

Cable Construction

- Circular bare copper-conductor of stranded wires to HD 383

- Inner semi-conducting coating

- Conductor insulation of cross-linked polyethylene (XLPE), PE-compound DIX8 to HD 620.1

- Outer extrusion of semi-conducting coating spliced with the insulation

- Wrapping of conductive material

- Shield: Braiding of copper wires with one or two tape(s) applied helically

- Wrapping

- PVC outer jacket, compound DMV6 to HD 620.1

- Jacket color: Red

Application

- Suitable for installation mostly in power supply stations, indoors and in cable ducts, outdoors, underground, and in water as well as for installation on cable trays for industries, switchboards, and power stations.

- Due to the good laying characteristic, this cable can also be installed in difficult line guideways.

- The inner conducting layer between the conductor and the XLPE insulation and the firmly bonded outer conducting layer on the XLPE insulation assures a construction free of partial discharges with high operational reliabilities.

Temperature Range

- During installation up to -5°C/+23°F

- Operating Temperature Max. +90°C/+194°F

- Short Circuit Temperature +250°C/+482°F (short circuit duration up to 5 sec.)

Nominal Voltages

- U0/U 6/10 kV, 12/20 kV, 18/30 kV

Operating Voltages

- 6/10 kV = max. 12 kV

- 12/20 kV = max. 24 kV

- 18/30 kV = max. 36 kV

Test Voltages

- 6/10 kV = 15 kV

- 12/20 kV = 30 kV

- 18/30 kV = 45 kV

Minimum Bending Radius

- During Installation Max. 15x Cable Ø

Technical Specifications

12/20KV N2XSY Cable

| NO. Cross-Section Area | Copper Wire Screen Area* | NO. Sheath Thickness | NO. Overall Diameter | Approx. Weight | ||

| N2XSY/N2XSH CU | N2XS2Y CU | N2XS (F) 2Y CU | ||||

| mm2 | mm | mm | mm | kg / km | kg / km | kg / km |

| 25 | 16 | 1.8 | 29 | 1000 | 900 | 1100 |

| 35 | 16 | 1.8 | 30 | 1100 | 1050 | 1200 |

| 50 | 16 | 1.8 | 31 | 1250 | 1150 | 1350 |

| 70 | 16 | 1.9 | 33 | 1500 | 1350 | 1600 |

| 95 | 16 | 1.9 | 34 | 1800 | 1650 | 1900 |

| 120 | 16 | 2.0 | 35 | 2150 | 1900 | 2250 |

| 150 | 25 | 2.0 | 37 | 2400 | 2250 | 2500 |

| 185 | 25 | 2.1 | 38 | 2800 | 2600 | 2900 |

| 240 | 25 | 2.1 | 42 | 3400 | 3200 | 3500 |

| 300 | 25 | 2.2 | 43 | 4000 | 3800 | 4150 |

| 400 | 35 | 2.3 | 44 | 4950 | 4750 | 5100 |

| 500 | 35 | 2.4 | 46 | 6050 | 5800 | 6200 |

| 630 | 35 | 2.5 | 50 | 8150 | 8050 | 8300 |

| 800 | 35 | 2.6 | 53 | 9600 | 9450 | 9800 |

Application Fields

Power supply stations

Indoor and cable duct installations

Outdoor and underground installations

Water installations

Cable trays for industries, switchboards, and power stations

Packaging & Shipping

All cables will be packaged in different materials based on their outer diameter and net weight, and can be customized according to requirements